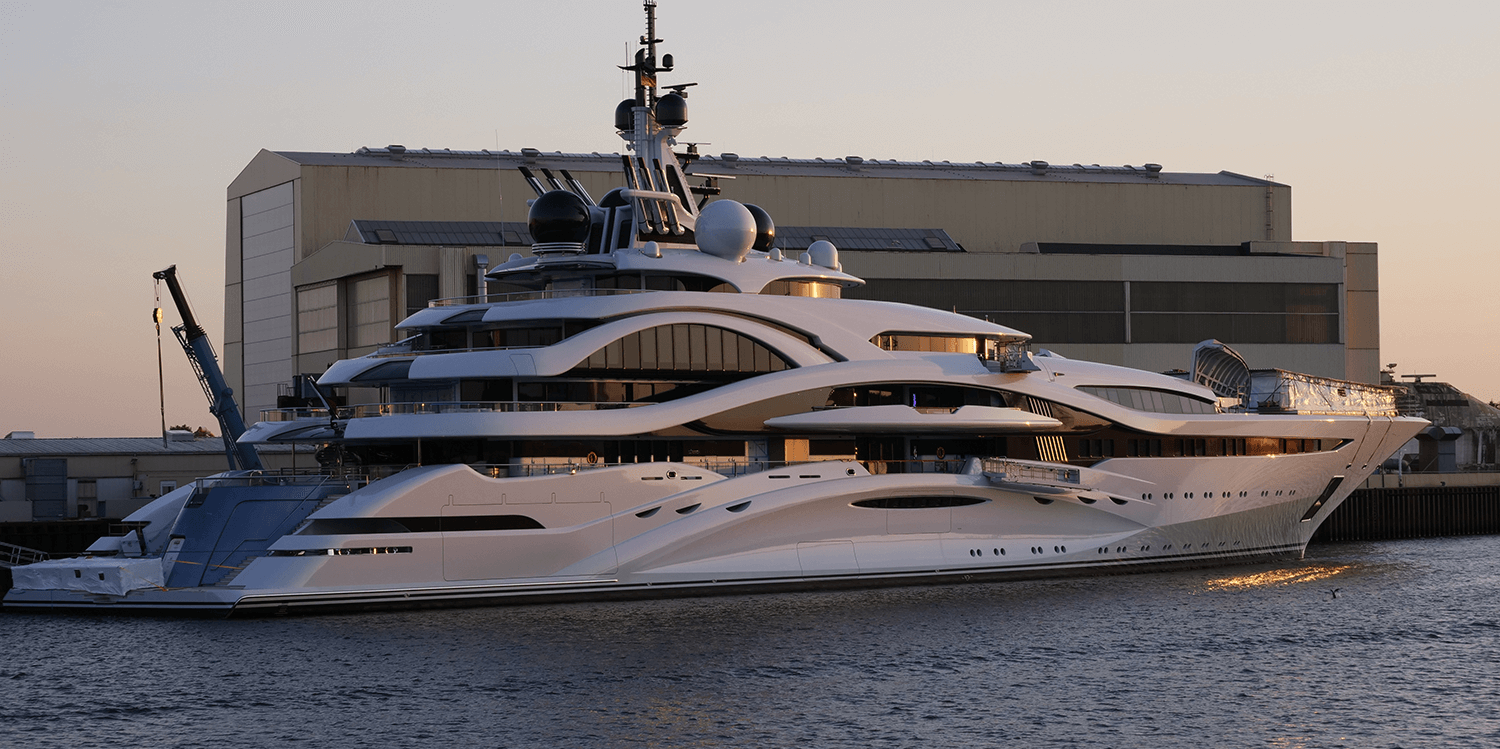

GRP Composite Lamination for Luxury Superyachts

Contact us

Hythe Marine Services (HMS) is expanding its capabilities within the luxury superyacht industry. The new composites lamination department will mainly be doing GRP (glass reinforced plastic) boat building and moulding of luxury yachts, working closely with the joinery department who will handle the decks and woodwork finishes.

Why is GRP Composite lamination so popular in the luxury superyacht industry?

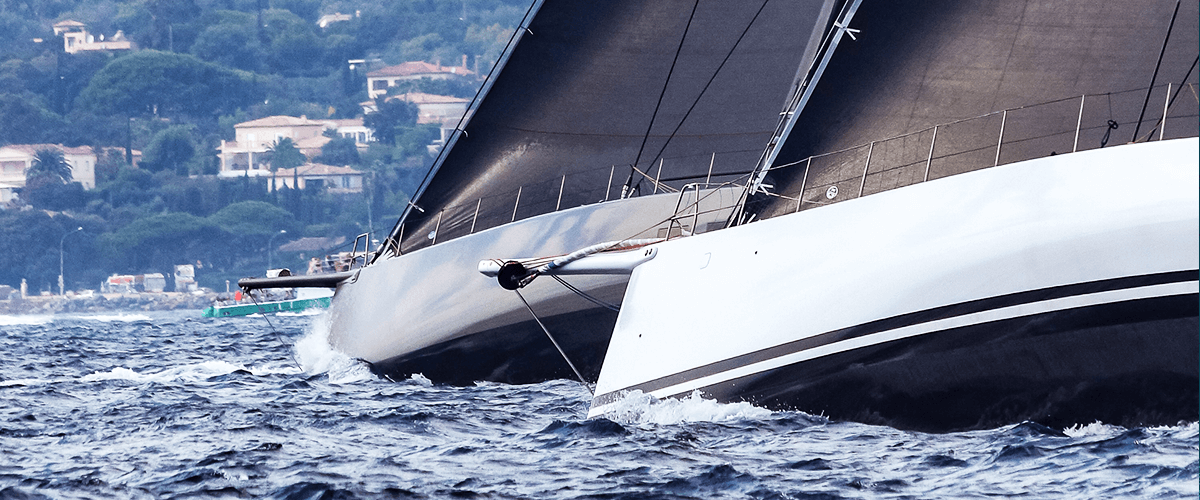

GRP laminating is a popular method within the superyacht boatbuilding industry because of its high strength properties once cured. Fibreglass is a durable, non-corrosive material, so it’s a first choice for the boatbuilding industry.

We spoke to a member of the team with composites expertise, who told us, “Fibreglass lamination is popular in boatbuilding for its ease of use, versatility and ability to be laid up in multiple layers.”

GRP is a lightweight material that can be used in many different forms for operations in superyacht building and repair work. Fibreglass mouldings can be sandwiched with all sorts of other materials including Balsa, softwood, hardwood and metals.

The team member explained, “Fibreglass mat in its dry form can be moulded into any shape, and into really tight corners, making it the number one choice for most superyacht boat builders.”

There are many different types of fibreglass lamination, including hand lay-up lamination and vacuum infusion lamination. In vacuum infusion lamination, the infusion is laid down in multiple layers of dry-stacked material and covered with breather membranes and a bag. This is then sucked down by a vacuum pump and resin is fed into the material under vacuum.

The advantages of vacuum infusion over hand lay-up are that the infused parts are so much lighter. Our representative told us, “Vacuum infusion lamination is advantageous when you’re building a product that has weight restrictions, such as with boatbuilding and superyachts.”

Speak with our team to discuss your next project!

Hythe Group’s expansion into the luxury superyacht industry

The lamination and joinery department will be working closely together on all luxury boat building projects. To facilitate Hythe Marine Services moving into the luxury superyacht boat building industry, the fibreglass lamination team will be moving into the new HMS workshop. Fibreglass lamination requires very specific working conditions, so the woodworking and metalworking workshops are being refitted to optimise the space for safety and quality.

Metalwork and woodwork have their own hazards, but a lamination moulding shed includes the risks from dealing with highly combustible and hazardous materials that deserve the utmost respect from the laminators. A moulding shed should be dust free and clean to keep your mould tools and mat suitable for laminating. The workshop must be kept at optimum moulding shed temperature and the fumes (styrene) extracted out of the moulding shed through proper ventilation.

HMS are ensuring every step to entering the luxury boat building industry is completed correctly and with the right people in the team. One of the team taking on this challenge said, “The luxury superyacht market is hard to break into. We will build up our reputation as a reputable composite department, by focusing on building trust with customers for boat repair work, builds and refits.”

What will Hythe Group’s new laminating department be doing?

In the workshop, the team will be managing and making the components for new contracts. One of the team commented, “We want to make sure the quality is better than what our customers are currently expecting, as we strive to deliver quality and in a time-controlled manner. We will be looking at securing contracts by putting out the feelers nationally and internationally and making the department grow, through building up trust and reputation.”

The composites department are kicking off with a big project at the naval base. This new HMS project involves making GRP panels for Royal Naval minesweepers. The fibreglass lamination process for this project includes building up multiple layers of fibreglass to a mould tool, making sure that they are air-bubble free, before curing the moulding by means of rolling out the layers. They will then be de-moulded from the mould tools and trimmed. Once they have been inspected and signed off, they can be delivered to the customer.

Eager to get stuck in, a member of the team expressed, “I’m really looking forward to the new challenge ahead and offering all my years of experience within a boat building and repair capacity. I have heard great things about HMS and can’t wait to see what we can achieve together.”

To discuss your next boatbuilding project contact our team via the button below.